-

Aluminiumlegierungscasting

-

Druck Druckguss-Form

-

Metall Gießformen

-

Aluminium-Druckguss Formenbau

-

ENV-Schaum-Form

-

Verlorene Schaum-Form

-

Sandguss-Form

-

permanente Form gießen Aluminium

-

Aluminium Kokillenguss

-

Sterben Gussaluminium-Werkzeugausstattung

-

Autoteil-Form

-

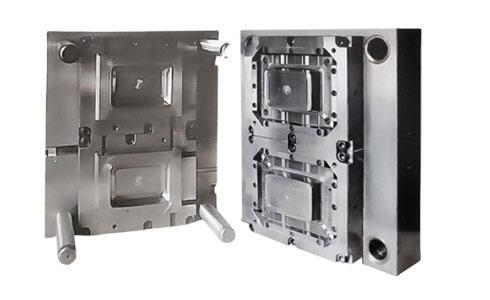

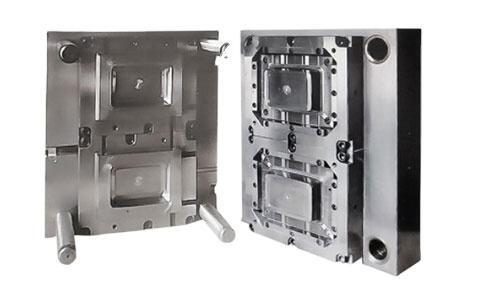

Multi-Cavity Mold

-

Zylinderkopf-Form

-

Form der hohen Präzision

-

Schneller 3d Druckservice

-

Greg HenkDank für Ihre kindly Gastfreundschaft. Ihre Firma ist, wir hat die nette Zusammenarbeit in naher Zukunft sehr Berufs.

Greg HenkDank für Ihre kindly Gastfreundschaft. Ihre Firma ist, wir hat die nette Zusammenarbeit in naher Zukunft sehr Berufs. -

Lionel-LoboGute Firma mit nettem Service und hohe Qualität und hohes Ansehen. Ein unseres zuverlässigen Lieferanten, Waren werden in Zeit und in nettes Paket geliefert.

Lionel-LoboGute Firma mit nettem Service und hohe Qualität und hohes Ansehen. Ein unseres zuverlässigen Lieferanten, Waren werden in Zeit und in nettes Paket geliefert.

Hersteller von Mehrfachkammer-Aluminium-Extrusionswerkzeug-Design

| Produktname | Multi Hohlraumform | Maßgeschneidert | Ja |

|---|---|---|---|

| Degrenzen | Automatisch | Unter Verwendung der Härte | >HRC45 |

| Schimmelleben | 50,000-100,000 Schüsse | Schimmelmaterial | EPS |

| Oberflächenbehandlung | Wärmebehandlung | Durchschnittliche Wandstärke | > 3 mm |

| Produktpalette | Autoteile, Licht, Industrie, Möbel | Typ | Verlorenes Schaumcasting |

| Hervorheben | Mehrfachkammer-Aluminium-Extrusionswerkzeug,Hersteller von Aluminium-Extrusionswerkzeugen,Designer von Mehrfachkammerwerkzeugen |

||

Multicapacity Aluminium Extrusionsformentwickler Hersteller

Mould Proudct Bereich

Transport, landwirtschaftliche Maschinen, Baumaschinen, Wasserpflegeeinrichtungen, Raumfahrt und Luftfahrt, chemische Maschinen, Seeverkehr usw.

Eigenschaften von Schimmelpilzen

- Technik mit präzisen und stabilen Abmessungen

- Einfach zu montieren und zu demontieren;

- Leichte Wartung

- Längere Lebensdauer

- Schönes Finish

- Hohe Festigkeit

- Robuste Konstruktion

- Dauerhafte Natur

Beschreibung des Produkts

|

Mehrhöhlenschimmelpilz

|

||

|

angepasst

|

||

|

Hot&Cold Runner

|

||

|

UG,CAD/CAM,PROE

|

||

|

Korrosionsbeständigkeit, Polierverfahren, Drahtziehbehandlung

|

||

|

Stickstoffbehandlung

|

||

|

CNC, Hochgeschwindigkeitsgravierungen, Drehmaschinen mit digitaler Steuerung usw.

|

||

|

Zehn Millionen Zyklen

|

||

|

ABS, PPR, PC, PP, PVC, POM, PMMA, PS, PE, PET, PA, PBT, PEI usw.

|

||

|

LKM oder nach Bedarf

|

||

|

HASCO, DME, Musumi oder nach Bedarf

|

Herstellungsprozess

2. Gestaltung und Herstellung von Formen und Werkzeugen

3. Formen- und Werkzeugprüfung und Bestätigung der Probe

4. Druckguss aus Rohguss

5- Oberflächenbehandlung: Trimming, Deburring, Polishing, Reinigung, Passivierung und Power Coating und sonstige Anforderungen des Kunden

6. Präzisionsbearbeitung: CNC-Drehmaschinen, Fräsen, Bohren, Schleifen usw.

7Vollständige Inspektion.

8- Packen.

9Lieferung.

![]()

Qualitätskontrolle

Wir kontrollieren den Produktionsprozess streng, indem wir Computer verwenden, um die Produktionsqualität zu verbessern und zu stabilisieren. VCU has its own highly qualified QC team equipped with all necessary and state-of-the-art testing equipment to be able to perform 100% inspection in order to ensure the best quality products that will be delivered to all of our customers.

Anwendbare Szenarien:

Unsere Formen werden häufig in der Herstellung von Aluminiumprofilen verwendet, die in der Lebensmittelindustrie, Verpackungsindustrie, Bau und Dekoration, Schiffen und Druckbehältern, Hochgeschwindigkeitsbahn,Luftfahrtkomponentenprodukte, wie z. B. leicht zu ziehende Tanks, Chemikalienlagerbehälter, Trennhäuser, mobile Räume, Offshore-Pipelines, Flugzeugskelett, Fensterprofile, Türprofile, Profile für Vorhangwände,die Profile für Sonnenenergie usw.Die häufigsten Spezifikationen sind 6061 und 6063.- Die Serie.

Dienstleistungen nach dem Verkauf

-

Nach jedem Test, wenn es Rückmeldungen zu Problemen gibt, werden wir innerhalb von 48 Stunden einen Korrekturplan oder einen Vorschlag zur Verfügung stellen.

-

Für Kunden, die regelmäßig Bestellungen abgegeben haben, wird der Vertriebsleiter alle sechs Monate technisches Personal mitbringen, um die wichtigsten Probleme bei der Verwendung von Formen zu verstehen und zusammenzufassen.und geben Feedback an die Designer für spätere Förderung und Verbesserung.

-

Für Kunden, deren Einkaufsvolumen ein bestimmtes Maß erreicht, kann das Unternehmen für eine gewisse Zeit einen Werkzeugkorrektor an den Standort des Kunden schicken, um die Korrektur und Wartung des Formensystems durchzuführen.

Verpackung und Versand

Wir verpacken alle unsere Produkte in Holzkisten, um sicherzustellen, dass sie keinen Schaden erleiden.Die Produkte werden Ihnen pünktlich zugesandt und wir werden alles von der ersten Beratung bis zur Lieferung an Ihren ausgewählten Hafen überall auf der Welt organisieren.Wir können auch die Verpackungsmethode entsprechend den Bedürfnissen der Kunden anpassen.

![]()

Unternehmensprofil

Luoyang Liushi Form Co., Ltd wurde im Jahr 2001 gegründet, die National Standard Setting Unit für Lost Foam Gießform ist.Stadt der Pfingstrose in der Stadt LuoyangWir haben 9800 Bürogebäude und 22000 Werkstätten, die gut mit Forschung, Entwicklung, Design, Gießerei, Bearbeitung, Montage, Oberflächenbehandlung und anderen Geräten ausgestattet sind.Es ist ein FuE- und Technologiezentrum der Stadt Luoyang..

Die Techniker des Unternehmens können die Vor-Ort-Anordnung von Führungsformen, die Testproduktion, die kostenlose Reparatur und die vollständige Technologie für die Verlust-Schaum-Gießprozesse gemäß den Anforderungen der Kunden bereitstellen.Mit der Geschäftsphilosophie "Sicheres Design"Nach jahrelanger Entwicklung sind wir bestrebt, Kunden mit zufriedenstellenden Produkten und Dienstleistungen zu versorgen.Unsere Firma ist der bevorzugte Formenlieferant von vielen verloren Schaumguss Hersteller und der exklusive Lieferant geworden.